The company has built a 470,000 ton/year rubber additive production project with a supporting wastewater treatment capacity of 2,000 m³/d, which is built in two phases. The company’s production wastewater mainly contains cyclohexylamine, aniline, nitrobenzene, ketones and other difficult-to-biodegrade organic pollutants, with characteristics such as large fluctuations in water quality and quantity, high pollutant concentration, difficult biodegradation, heavy color, and strong odor.

Handling Process

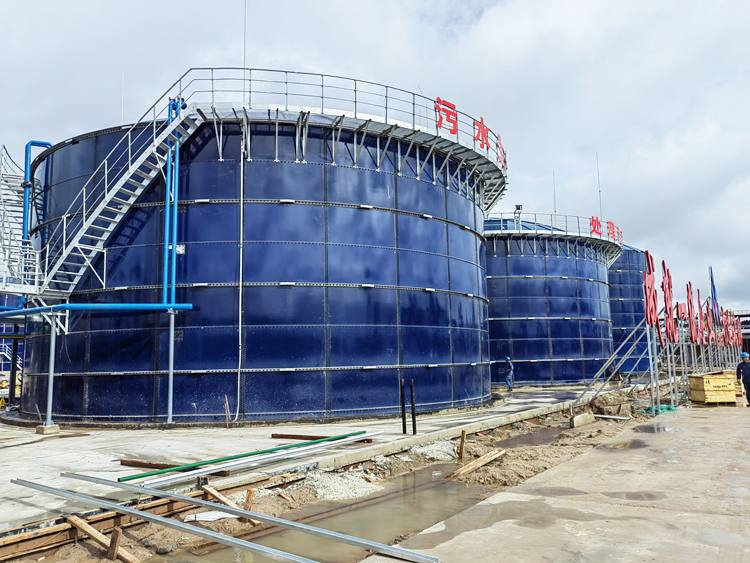

- This project adopts the combined process of “Ozone Pretreatment + A/O Bio-Enhancement Biochemical Treatment + Improved Fenton Deep Treatment“.

- The oxidizing property of ozone is used to reduce the biological toxicity of organic pollutants and improve biological adaptability. Then, the various pollutants in the wastewater are degraded and removed mainly by the bio-enhancement process. Finally, the improved Fenton deep treatment process is used to ensure that the effluent is stable and meets the discharge standards.

- The main structure of the project innovatively adopts the assembled enamel assembly tank structure, which has the advantages of corrosion resistance, fast construction speed, small footprint and low project cost.

Service Achievements

In case of inlet water CODcr 3000-4000mg/L, Aniline about 500mg/L, Nitrobenzene about 100mg/L, Ammonia Nitrogen about 300mg/L, the treatment outlet water CODcr ≤ 80mg/L, Aniline ≤ 1mg/L, Nitrobenzene ≤ 2mg/L, Ammonia Nitrogen ≤ 15mg/L. The cost of wastewater treatment is about 5rmb/m³.

Contact Us

You are welcome to contact us by REC E-mail. You can also fill out the company information form online or message us. We will contact you as soon as possible.

-1.jpg)